Manufacturing Production Efficiency Counter Display w/Webpage Viewing & CSV Log for Chemical Company

- By : DC-Digital sales & marketing

- Category : Counters, Data Controlled Displays, Manufacturing, Production Counter

- Tags: counter, DC-25, Dc-Digital, efficiency, Network Browser Based Displays no software required, network controlled computer controlled safety scoreboard days without incident accident first aid, Network Controlled Displays, Production Counter

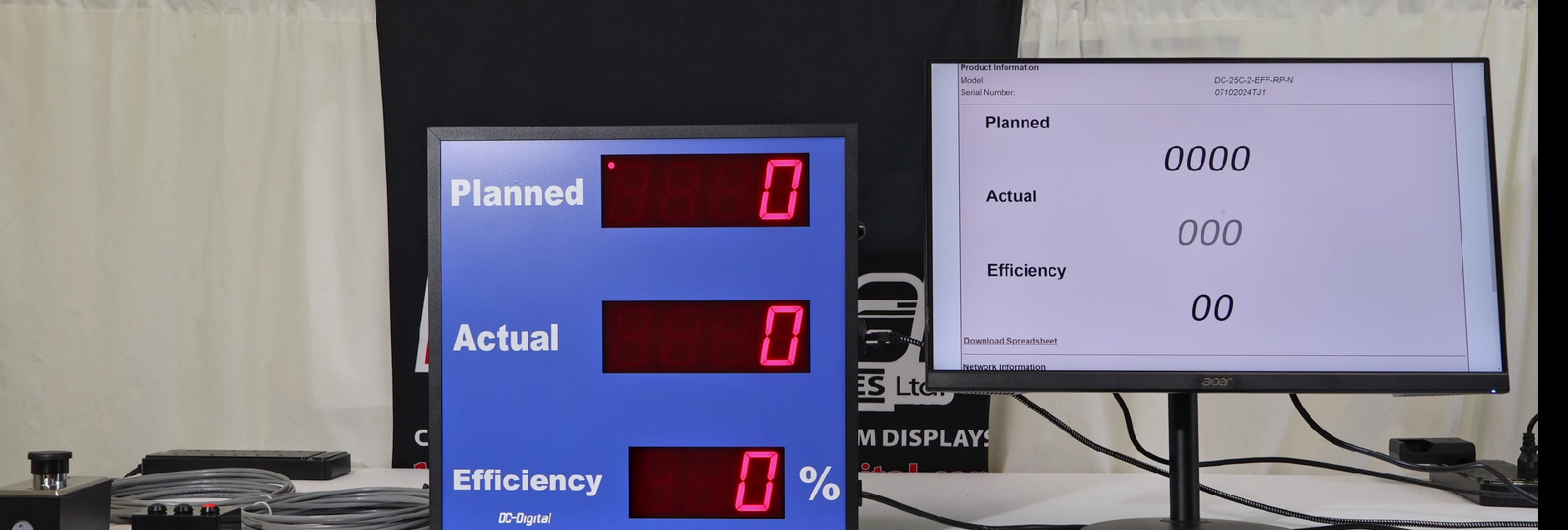

The DC-25C-2-EFF-RP-N Counter, Network, Times was custom-built for PSG Dover to provide real-time visibility into production efficiency by directly comparing planned output versus actual performance. This system enables teams to accurately measure efficiency rates across products and services using network-based timing and count data, giving operations a clear, actionable view of performance without the need for third-party software or external installations.

At the core of this solution is the ability to define a planned production quantity and track actual output as work progresses. The unit automatically calculates efficiency by comparing the planned amount against the actual count, updating the efficiency percentage in real time. This data is simultaneously made available on a secure, internal network webpage that is completely free to use and accessible from anywhere on the customer’s network, allowing supervisors, engineers, and managers to monitor production without being physically present on the floor.

The planned count is set using dedicated push button switches on the enclosure. Operators can increment values one digit at a time or press and hold to rapidly advance the count for faster setup. A decrement button allows for precise adjustments, while a press-and-hold zero reset clears the planned value when needed. Once the planned quantity is set, the built-in up-timer can be started and stopped using a control mounted on the side of the enclosure, clearly indicating when timing is active.

As production begins, the actual count is recorded using a wired palm switch. Each press increments the actual total and immediately updates the efficiency rating, allowing teams to see how current performance aligns with production goals. The integrated timer captures the elapsed time between each count, creating a detailed record of production pace that reflects both active production time and downtime.

Beyond the physical display, the network functionality expands the value of the system even further. All counts and time intervals are logged to a network-accessible webpage, where users can view performance data in real time or download a complete spreadsheet of results. This includes a timestamped record of every button press, part completion time, and downtime interval, enabling PSG Dover to analyze process flow, identify inefficiencies, and evaluate cycle times at a granular level. Over time, this data supports process optimization, staffing decisions, and continuous improvement initiatives.

Key capabilities of the DC-25C-2-EFF-RP-N include:

- Real-time efficiency calculation based on planned versus actual output

- Integrated up-timer for tracking production and downtime

- Network-based webpage for live monitoring and data logging

- Spreadsheet export of individual counts and time intervals

- No required third-party software or external installations

From a hardware perspective, the unit is housed in a durable aluminum enclosure with a black powder-coated finish designed to resist fingerprints and dust in industrial environments. The enclosure measures approximately 16 inches wide, 15.75 inches tall, and 2 inches deep. Each display section features 2.3-inch digits with visibility up to 120 feet, ensuring clear readability across the production floor. The planned and actual counters each support four digits up to 9,999, while the efficiency display supports three digits up to 200.

The system operates on a 120–240 VAC power supply with a 6-foot cord and includes adjustable teardrop mounting tabs for secure wall installation. Accessories provided with this configuration include a wired palm switch for actual counts and environmentally sealed push buttons for setting the planned quantity, each supplied with 25 feet of cabling. The network webpage log completes the system by allowing configuration, monitoring, and long-term tracking of production timing and efficiency data.

This custom DC-25C-2-EFF-RP-N solution gives PSG Dover a powerful, data-driven tool to measure, analyze, and improve operational efficiency with precision and confidence.

See similar product: DC-25C-2-EFF-RP

See tutorial video on YouTube

See DC-Digital Store

Contact us to ask about our customized products!

No Comments