Package Counter that Measures Efficiency Rate of Production w/ Area Sensors & Wired Remote for Corporate Food Companies

- By : DC-Digital sales & marketing

- Category : Counters, Production Counter, Scoreboard

- Tags: actual, Area Sensors, assembly, clock, Counters, Dc-Digital, efficiency, photo-optic-eye-sensors, planned, Process-Counter, Production Counter

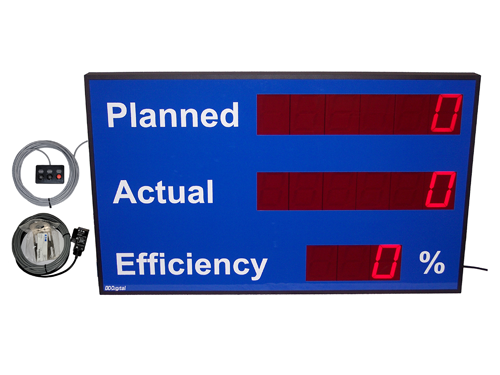

Campbell’s Snacks came to DC-Digital with a specific need—an easy-to-use, high-visibility production counter for their assembly line that could help them monitor performance and stay on track with production goals. In response, we custom-built the DC-406C-2-EFF-SENS, a dual-sensor counter that provides real-time data on actual vs. planned production output, while also calculating overall line efficiency.

This unit doesn’t rely on a traditional pace-of-production program. Instead, we implemented a simple 3-button controller with functions for incrementing, decrementing, and resetting production plans. That level of simplicity allows operators to quickly adapt the system for each shift or production run.

Key Features of the DC-406C-2-EFF-SENS:

- Three-panel display: shows the planned number of units, actual units produced, and efficiency percentage.

- Efficiency calculation: Real-time updates up to 200% based on actual vs. planned totals.

- Dual photoelectric sensors: Each line on the production floor is equipped with a sensor that contributes to the overall product count.

- Sensor range: Adjustable infrared sensors can detect solid objects up to 10 feet away.

- Versatile mounting: Each sensor comes with stainless steel mounts and 25 feet of cable. Mounting is straightforward using adjustable tabs and thermal blocks.

- 4-inch high digits with six-digit capacity: Ensures visibility from a distance and accommodates high-volume tracking.

The counter was designed to allow flexibility in how production teams operate. The planned value can be adjusted at three speeds via the increment button for fast setup. If a value is set too high, the decrement button brings it down at a slower, more controlled pace. A full reset is available to clear the plan and actual counts, recalibrating efficiency in real time.

From a hardware standpoint, the unit is encased in an all-aluminum enclosure with a durable acrylic Lexan vinyl front. The high-brightness LED digits ensure clear readability in an industrial setting. The counter is powered using a 24V system, and we provide a 24V power supply for standard 120V wall outlets with each unit, making integration into existing setups seamless.

Designed for the Demands of Modern Assembly Lines

This counter was built specifically to serve a dual-line environment—ideal for facilities with two conveyor lines or tracking multiple output streams. Since both sensors contribute to the actual count, users don’t need to micromanage which line contributes what. The system adds up everything automatically and displays the data without any delay.

With just a few button presses, teams can:

- Set or adjust their production goals.

- Track actual outputs in real time.

- Monitor and improve their efficiency, shift by shift.

By offering visibility into the gap between planned and actual output, the DC-406C-2-EFF-SENS helps teams stay accountable and optimize operations. It’s a practical solution that delivers powerful insights without unnecessary complexity.

Built by DC-Digital—Engineered for Customization

This project highlights our continued commitment to building custom digital timing and counting systems tailored to each client’s unique workflow. If your team needs production counters, efficiency tracking, or sensor-based display systems, DC-Digital can create a solution that works for your process—not the other way around.

See product: DC-406C-2-EFF-SENS

See tutorial video on YouTube

Visit our home page

Contact us to ask about our customized products!

No Comments