The HALT (Highly Accelerated Life Test) LED Counter Display System by DC-Digital

The HALT (Highly Accelerated Life Test) LED Counter System, designed for Qorvo Inc. This innovative system combines precision, redundancy, and user-friendly controls to streamline testing processes and ensure accurate data collection.

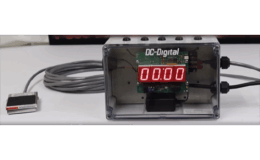

Introducing the DC-40C-Term-Key-Max-RLY, a fully customized counter display solution engineered for durability testing and automated cycle control applications. This system integrates a high-visibility numeric display, keypad interface, polarized reflective sensor, and relay output into one cohesive package designed to monitor, control, and protect high-cycle machinery.

In this application, the DC-40C-Term-Key-Max-RLY is configured for a durability testing lab where parts are repeatedly hammered for thousands of cycles. The polarized reflective sensor detects each stroke of the hammer, accurately counting operations in real time. Once the programmed maximum cycle count is reached, the system automatically activates a relay to shut down the machine, preventing over-testing and ensuring precise repeatability.

The integrated keypad allows operators to easily program and manage the system directly from the front panel. Using the numeric keys (0–9) along with dedicated function buttons, users can:

- Set or view the maximum cycle count

- Enter and confirm programmed values

- Clear the current count

- Toggle between Run and Pause modes

- Reset and restart operations

Before operation begins, a maximum count must be programmed using the “Set Max Count” function. Once entered and confirmed, the unit is placed into Run mode, enabling the sensor to begin counting. When the preset limit is reached, the relay output activates and the machine stops automatically. The count can then be cleared for repeat testing or adjusted for a new maximum cycle requirement.

The Run/Pause functionality provides operational flexibility. If maintenance is required or the sensor is accidentally triggered, operators can exit Run mode to temporarily halt counting without losing progress. Re-entering Run mode resumes counting from the stored value. The programmed maximum count is stored in nonvolatile memory, ensuring retention even if power is removed.

To accommodate different sensor mounting positions and mechanical stroke patterns, the DC-40C-Term-Key-Max-RLY includes configurable DIP switch settings that determine how the sensor registers counts:

- Count on every beam break (both directions)

- Count on upstroke only

- Count on downstroke only

This flexibility allows accurate counting whether the sensor is positioned at the top of the anvil stroke or elsewhere along the travel path.

The system also supports a secondary display output, enabling redundant count monitoring in another location within the facility. This makes it ideal for supervisory viewing, production oversight, or remote personnel monitoring.

Additional hardware and installation features include:

- Integrated RS-485 communication capability

- Clearly marked terminal blocks for sensor wiring

- Relay output terminals (1, 2, 3)

- Modular front and rear separation for serviceability

- Rear-mounted sensor interface board

- Multiple cable entry points (rear center or left side)

- Four-square or handy box mounting compatibility with keyhole knockouts

- Durable aluminum enclosure

- 4-inch high display digits (with scalable options from smaller formats up to 30-inch digits)

The DC-40C-Term-Key-Max-RLY delivers precision counting, controlled shutdown functionality, flexible sensor configuration, and scalable display options in a rugged industrial enclosure. Whether used in durability testing, repetitive cycle monitoring, or automated machine control applications, this system provides reliable performance and operator-friendly control in demanding environments.

See similar product: DC-40-Static-Key

Watch tutorial video on YouTube: DC-40C-TERM-KEY-MAX-RLY

See other customized displays: DC-Digital Blog

Visit DC-Digital website

Contact us to ask about our customized products!

No Comments