Factory Production Counter Emits Count Tone, Andon Light and Calculates Efficiency

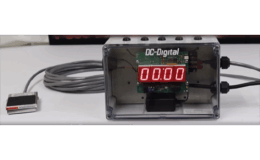

Real-time efficiency tracking is at the core of this custom DC-25C-2-EFF-Keypad-Sensory Technology Production Counter built specifically for Valcom Inc., a technology manufacturing facility focused on monitoring and improving the rate at which their products are assembled by hand.

This custom order is designed to give Valcom Inc. immediate visibility into how efficiently their team is producing parts in real time. By comparing a pre-set “Planned” production pace against the live “Actual” count captured on the floor, the system continuously calculates and displays the efficiency rate—allowing supervisors and operators to quickly determine whether production is on target, ahead of schedule, or falling behind.

At the center of this setup is our 24-key wired remote programmer controller. Using the keypad, operators can input a desired production pace directly into the “Planned” section. The unit offers three flexible production modes so it can match a variety of workflow requirements:

- Set Parts Per Second

- Set Parts Per Minute

- Set Seconds Per Part

For example, when using the “Set Parts Per Minute” function, the operator simply presses the corresponding button. The red LED digits in the Planned section begin flashing, indicating that the unit is ready for input. If the goal is 25 parts per minute, the operator enters “2” and “5,” then presses “Enter and Start.” The flashing stops, and the Planned count begins incrementing automatically at 25 parts per minute. From that point forward, the display steadily increases at the defined pace, representing the expected output.

As products are physically assembled, each completed part is passed through the DC-Sensory-10 diffused reflective area sensor. Every time an object moves through the detection field, the “Actual” section increments by one. Simultaneously, the green Andon light flashes and the integrated piezo alarm sounds for three seconds, providing clear visual and audible confirmation that a part has been successfully counted.

The system then compares Planned versus Actual in real time and calculates the efficiency percentage. If the Actual output exceeds the Planned pace, the efficiency rate climbs above 100 percent. In high-performance scenarios, the unit can display up to 200 percent efficiency, clearly indicating that production is outperforming expectations.

Operators also have full control over the process:

- Pause and Resume button temporarily halts both Planned and Actual counts, with flashing LEDs indicating pause status

- +1 Actual allows manual incrementing of the Actual count

- -1 Actual allows correction if an extra count was registered

- Resetting modes automatically clears the Actual and Efficiency sections when switching production methods

The “Set Parts Per Second” mode allows for faster-paced operations. After entering the desired number and pressing Enter and Start, the Planned section increments rapidly according to the defined per-second rate. Both the Planned and Actual sections feature four digits and can count up to 9999. The Efficiency section uses three digits and can calculate up to 200 percent.

The “Set Seconds Per Part” mode provides another level of flexibility. By entering the number of seconds per unit, the system increments the Planned count accordingly—ideal for operations that are standardized around cycle time rather than volume.

Beyond functionality, this unit is engineered for durability and visibility on the production floor. The enclosure is constructed from tough extruded aluminum with a black powder-coated finish that is resistant to dust and fingerprints. The 2.3-inch LED digits are viewable from up to 120 feet away, ensuring that operators and supervisors can monitor performance at a glance across the facility.

Key hardware and accessory features include:

- Extruded aluminum, black powder-coated enclosure

- 2.3-inch high-visibility LED digits

- Four-digit Planned and Actual displays (up to 9999)

- Three-digit Efficiency display (up to 200%)

- 120–240 VAC three-prong wall adapter

- Adjustable rear teardrop mounting tabs

- 24-key wired remote programmer with 25 ft cable

- DC-Sensory-10 diffused reflective area sensor (detects up to 10 ft)

- Green Andon light with integrated 3-second piezo alarm

With this custom DC-25C-2-EFF-Keypad-Sensory Technology Production Counter, Valcom Inc. now has a powerful real-time performance monitoring solution that clearly measures the efficiency rate at which their products are made by hand. By combining programmable planned pacing, automated sensory counting, and instant efficiency calculation, this system provides the visibility needed to optimize workflow, maintain accountability, and continuously improve production output.

See similar Product: DC-25C-2-EFF-KEY-PACE-SENS

See tutorial video on YouTube

No Comments