6-Digit, Carpet Wear Gauge Product Counter w/ Area Sensor & Junction Box for Metal Factory Workers

- By : DC-Digital sales & marketing

- Category : Counters, Production Counter

- Tags: 6-digits, Area Sensors, counter, DC-10, Dc-Digital, Junction Box, Production Counter, Stainless Steel Switches

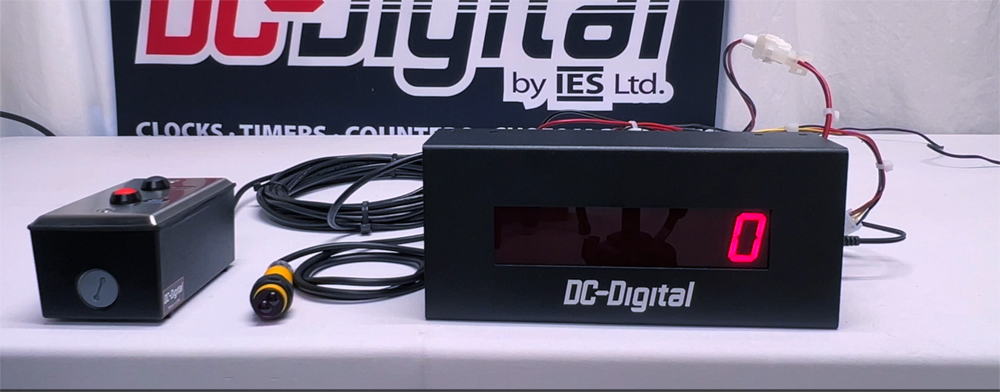

The DC-10C-PKG-SHRT Carpet Wear Gauge Testing Counter was custom-built for Signal Machine to support precise carpet wear and tear testing within a controlled gauge testing environment. Designed for reliability and ease of use, this unit provides an accurate method for tracking the number of times a material or object passes through a test cycle, helping ensure consistent data collection and repeatable results during durability testing.

At the core of this system is a diffusive reflective area sensor that detects each pass of an object through its sensing range. Every detection automatically increments the count, allowing operators to track wear cycles in real time as testing progresses. This hands-free counting method helps eliminate manual tracking errors and improves overall testing efficiency, especially in repetitive or high-volume test scenarios.

To give operators full control over the counting process, the system includes an environmentally sealed push-button junction box. This allows the user to decrement the count when adjustments are needed or reset the display back to zero at the start of a new test sequence. This flexibility is particularly useful during calibration, retesting, or when validating specific wear thresholds.

Key functional capabilities of the DC-10C-PKG-SHRT include:

- Automatic count incrementing via diffusive reflective area sensor

- Manual count decrementing using the junction box control

- One-touch reset to zero for quick test restarts

- Clear, easy-to-read display for real-time monitoring

From a hardware standpoint, this model is built for durability in industrial testing environments. The enclosure is constructed from black powder-coated, 14-gauge aluminum, providing long-term protection for internal components. The compact form factor allows the unit to be easily integrated into existing test setups without taking up excessive space.

Hardware specifications and physical features include:

- Enclosure dimensions: 6 inches wide, 3 inches tall, and 2 inches deep

- Display size: 1 inch tall, viewable from up to 25 feet

- Six-digit display with a maximum count of 99,999

- 120–240 VAC power wall adapter with a 6-foot cord supplying 12 volts

- Two slotted teardrop knockout drops on the rear of the enclosure for mounting

Included accessories complete the system and simplify installation. The diffusive reflective area sensor is capable of detecting objects within a 10-inch range, making it well-suited for controlled wear testing applications. The environmentally sealed push-button junction box includes 25 feet of cabling and connects to the enclosure through an opto base board located on the lower left rear interior. The area sensor is powered through an internal terminal block for a clean and organized wiring layout.

Overall, the DC-10C-PKG-SHRT Carpet Wear Gauge Testing Counter delivers dependable counting accuracy, operator control, and rugged construction, making it an ideal solution for carpet wear and tear testing, material durability analysis, and repeatable gauge testing processes in industrial and manufacturing environments.

See similar product

Watch tutorial video on YouTube

See DC-Digital Store

No Comments