Custom, NEMA Countdown Timer that Loops Indefinitely with 3 Push Button Switches for Steel Production Company

- By : DC-Digital sales & marketing

- Category : Countdown Timer, Manufacturing, Timers

- Tags: BCD rotary, Countdown Timer, countdown-timers, Dc-Digital, Factory Production Timer, Nema 4 enclosed, PLC

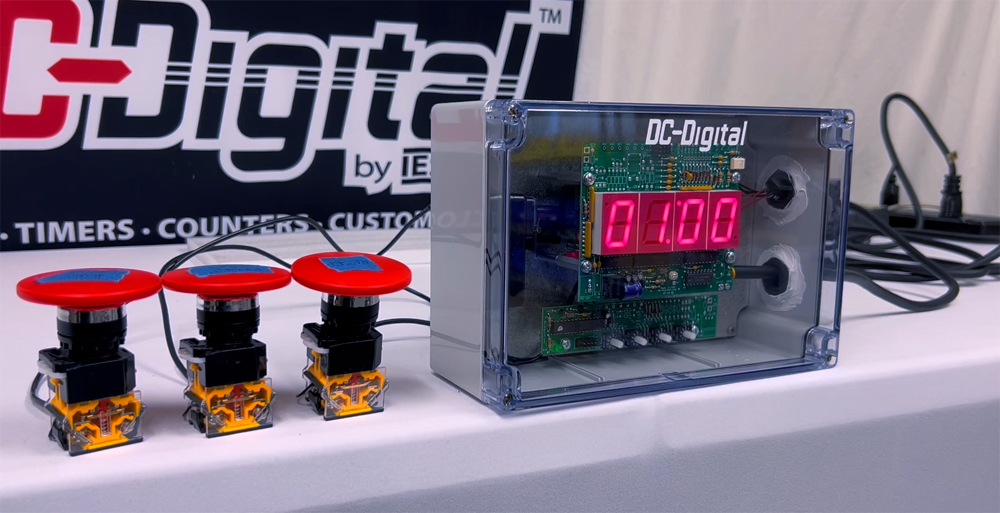

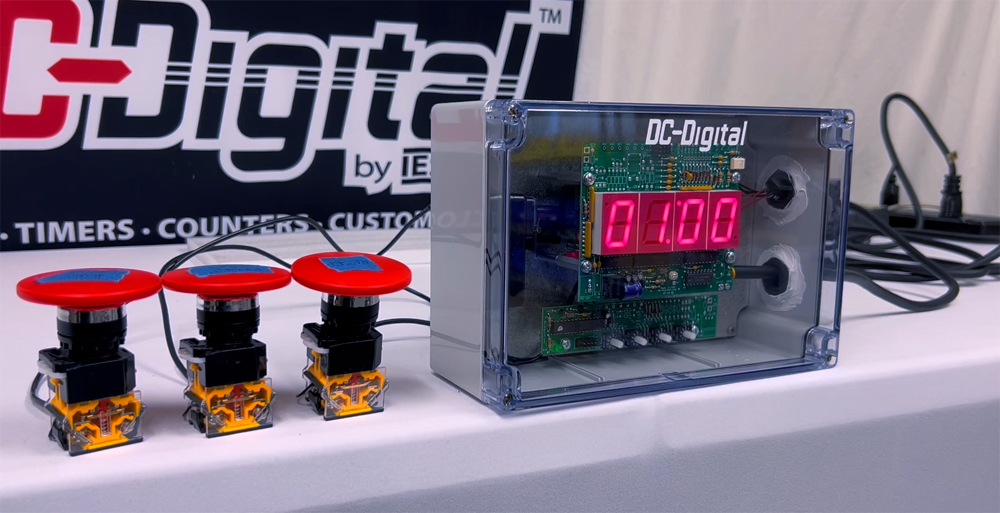

US Steel reached out to DC-Digital for a method of regulating the pace of their steel smelting production. The DC-10T-DN-BCD-LAZ-NEMA Countdown Timer is a custom-built industrial timing device designed for applications that require precise, repeatable cycle control with uninterrupted looping operation. This model is used to regulate process pacing by counting down from a fixed, user-defined time and automatically restarting when the countdown reaches zero. Its continuous loop functionality makes it ideal for production environments where consistent timing directly impacts output quality, throughput, and process stability.

Time configuration is accomplished through internal BCD rotary switches, which allow the user to preset the exact countdown duration with high accuracy. The programmable range extends up to 99 minutes and 59 seconds, providing flexibility for both short and extended cycle times. Because the BCD switches are mounted inside the enclosure, the programmed value remains protected from accidental adjustments during operation. Once set, the timer repeatedly counts down from the preset value to zero and immediately resets back to that same value to begin the next cycle.

Key timing and preset functions include:

- BCD rotary switches used to define the countdown duration

- Preset values retained until manually changed

- Automatic reset and restart when the timer reaches zero

- Continuous looping operation without operator intervention

Control of the countdown is handled through PLC-style momentary push button contact closures, allowing operators or external systems to regulate the flow of time without modifying the preset value. These controls provide direct, responsive interaction with the timer and are commonly integrated into industrial control schemes.

The push button functions include:

- Start/Stop: Initiates or pauses the active countdown

- Restart: Resets the timer to the preset value and immediately begins counting down

- Reset: Returns the display to the preset time without starting the countdown

All push button inputs are wired to an internal terminal block, ensuring secure connections and straightforward troubleshooting. The timer operates silently, with no audible buzzer or mechanical relay noise. When the countdown reaches zero, the display instantly resets and resumes timing from the preset value, maintaining uninterrupted process flow.

The DC-10T-DN-BCD-LAZ-NEMA is built for use in demanding industrial environments and is housed in a polycarbonate, air-tight sealed enclosure. The enclosure carries NEMA 4X, 6, 6P, 12, 12K, and 13 ratings, as well as an IP-66 ingress protection rating, providing resistance to water, dust, and industrial contaminants. The polycarbonate material is UL49 flammability rated, offering enhanced protection in heat-intensive or hazardous locations.

Enclosure and mechanical features include:

- Polycarbonate construction with flame-resistant properties

- Fully sealed, water- and dust-resistant design

- Compact enclosure measuring 6 inches wide, 6 inches tall, and 2 inches deep

- Four rear through-holes for secure wall or panel mounting

For clear time visibility, the timer features a 1-inch LED, four-digit display that can be read from distances of up to 25 feet. The display supports minute-and-second resolution, allowing operators to easily monitor remaining cycle time at a glance.

Display and electrical specifications include:

- Four-digit LED display with 1-inch digits

- Maximum display range of 99 minutes and 59 seconds

- 120–240 VAC power input

- 9-foot SJEOOW NEMA 5-15 power cord

- Internal grounding to the enclosure for safety and compliance

This countdown timer is commonly deployed in manufacturing and process-control applications where consistent cycle timing is essential. Typical uses include steel and metal production, smelting and heat-treatment processes, industrial batching, machine cycle regulation, assembly line pacing, and automated process control. The DC-10T-DN-BCD-LAZ-NEMA provides a durable, accurate, and easy-to-integrate timing solution for industrial environments that demand long-term reliability and precise control.

See similar product: DC-10T-DN-NEMA

See tutorial video on YouTube

Visit DC-Digital Store

Contact us to ask about our customized products!

No Comments