Truck Loading-Unloading Package Timer with Rate per Hour

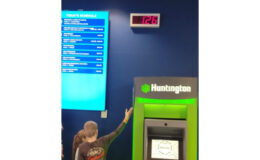

Efficiency, visibility, and precision — these are the driving forces behind our latest custom order, the DC-40C-Rate-Min. Designed specifically for FedEx, this custom-built digital rate display provides real-time monitoring of package loading rates per hour. It’s a practical solution that bridges performance tracking with human-centered design, ensuring both productivity and sustainability for the workforce.

Unlike the standard “Rate-Min” model that calculates rates per minute, this custom order has been engineered to display rate per hour. This modification was developed to better fit FedEx’s operational goals — measuring how many packages are being loaded per hour while maintaining an efficient yet manageable workload for employees during an eight-hour shift.

Integrated with the DC-DIF-S-10 Sensor

To achieve accurate and automatic counting, the DC-40C-Rate-Min works in conjunction with our DC-DIF-S-10 sensor — a 10-foot diffused reflective sensor that detects motion or the presence of objects. Every time the sensor is triggered, the system registers one count, which is then converted into an hourly rate on the bright LED display.

This setup allows FedEx to monitor:

- Loading rates per hour — ensuring that productivity goals are met.

- Worker pacing — helping balance efficiency with physical sustainability.

- Operational visibility — allowing supervisors to assess performance in real time.

Built for High Visibility and Industrial Use

Visibility and durability were key requirements for FedEx’s logistics environment. To meet those demands, the DC-40C-Rate-Min features:

- A 4-inch bright red LED display visible from up to 200 feet away, ensuring clear readability in large facilities.

- A 14-gauge, all-aluminum extruded enclosure for rugged, long-term use in industrial settings.

- Multiple mounting options, including compatibility with a junction box or a four-square electrical box.

- Cable entries on both sides and through the back for flexible sensor and power connections.

- 120VAC power input and pigtail junction box with terminal blocks for simplified installation and integration with sensors.

Smart Functionality in Action

In operation, the sensor detects each movement or package loaded, triggering the display to update instantly. For example, if the rate display shows a 786 count per hour, supervisors can immediately assess whether that rate meets the desired target threshold — ensuring that employees are loading efficiently without exceeding a sustainable pace.

The DC-40C-Rate-Min not only supports accurate rate tracking but also serves as a motivational performance tool, helping employees visualize progress in real-time while management maintains oversight of team efficiency.

Why It Matters

For FedEx, this system provides a dual benefit:

- Operational Efficiency – guaranteeing that trucks are loaded at an optimal rate per hour.

- Human Sustainability – ensuring that workers maintain a pace that supports their well-being throughout a full shift.

The DC-40C-Rate-Min and DC-DIF-S-10 sensor together create a streamlined, data-driven approach to workforce monitoring — turning simple counts into actionable performance insights.

DC-Digital’s custom-built solutions continue to empower organizations like FedEx with real-time visual data that enhances productivity, accountability, and safety. Whether it’s tracking counts, rates, or time, our displays are engineered to perform with precision in the most demanding industrial environments.

No Comments