Production Rate and Efficiency Display with Automatic Rate Calculation w/ Wired Keypad & Plug N’ Play Switch

- By : DC-Digital sales & marketing

- Category : Counters, Keypad Controlled, Manufacturing, Production Counter

- Tags: actual, Dc-Digital, efficiency, Keypad entry, planned, Production Counter, Wired Keypad

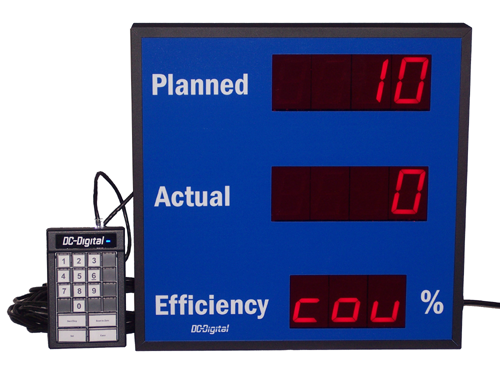

We’re excited to introduce our latest innovation — the DC-25C-EFF-PACE Pace Efficiency Counter — a newly programmed, upgraded version of our existing DC-25C series. This compact, versatile device is designed to help you track unit counts over a set duration and instantly calculate efficiency, with the ability to show results up to 200% efficiency. Whether you’re in manufacturing, quality assurance, packaging, or even sports training environments, this counter provides immediate and easy-to-read feedback on your performance pace.

Key Features of the DC-25C-EFF-PACE

- Live Pace Calculation: Calculates the number of units completed in a defined duration.

- Efficiency Display: Shows operational efficiency from 0% up to 200%.

- Adjustable Count & Duration Settings: Customize both the expected count and time goal.

- Universal Input Compatibility: Accepts both PNP and NPN sensor inputs.

- Aluminum Enclosure: Built with durability in mind using a robust, all-aluminum housing.

- Large, Clear Display: Includes 2.3″ high digits across three four-digit displays.

- Extended Timing Capability: Supports durations up to 99 minutes and unit counts up to 999.

How It Works

The DC-25C-EFF-PACE was demonstrated using a 60mm palm switch to simulate unit completions. This switch acts as a sensor — similar to what you might use in a production line, training exercise, or processing station. When you press the button, it mimics an action such as product completion or task cycle.

Here’s a breakdown of the programming process:

- Set the Target Duration:

- Example: You want to complete 10 units in 25 seconds.

- Input 25 seconds and press enter.

- Set the Target Count:

- Enter the number of units (e.g., 10).

- Press enter again to lock it in.

- Start the Session:

- Hit the start button and begin performing actions.

- Each press of the palm switch simulates a sensor trigger or task completion.

As you perform, the unit counts increment and the timer tracks how long it takes. If you finish 10 units in 25 seconds or less, the display confirms 100% efficiency — and if you’re faster, it can show up to 200%.

Wiring and Installation

The DC-25C-EFF-PACE is designed for quick installation and easy wiring. On the rear panel:

- Contact Closure and PNP Wiring Terminals:

- Inputs for common, power, and sensor signal.

- Onboard power terminals can supply voltage for sensors or photocells.

- Keypad Connection:

- Simple three-wire setup: 5V, common (blue), and data (orange).

- Keypad connects with four screws to the back panel.

- Mounting:

- Comes with three adjustable teardrop hangers for wall or structural mounting.

- Includes a 6-foot grounded cord for plug-and-play operation.

Final Notes

The DC-25C-EFF-PACE is a smart, industrial-grade solution for any environment that needs to monitor pace and performance in real-time. Whether tracking production runs, event timing, or task efficiency, this unit provides accurate, easy-to-read feedback with minimal setup.

- Real-time feedback on pace and progress

- Ideal for assembly lines, sports training, quality control, and more

- Durable build with easy-to-configure features

Upgrade your process with confidence. The DC-25C-EFF-PACE is engineered for performance, built for reliability, and ready to help you achieve operational excellence.

See tutorial video on YouTube

See MORE INFORMATION on this product: DC-25C-2-EFF-KEY-PACE-AUTO

Visit DC-Digital website

Contact us to ask about our customized products!

No Comments