Automated Production Counting and Efficiency Monitoring System for Pharmaceuticals

- By : DC-Digital sales & marketing

- Category : Counters, Number Displays, Production Counter

- Tags: Area Sensors, Dc-Digital, efficiency, Large LED Display, Production Counter

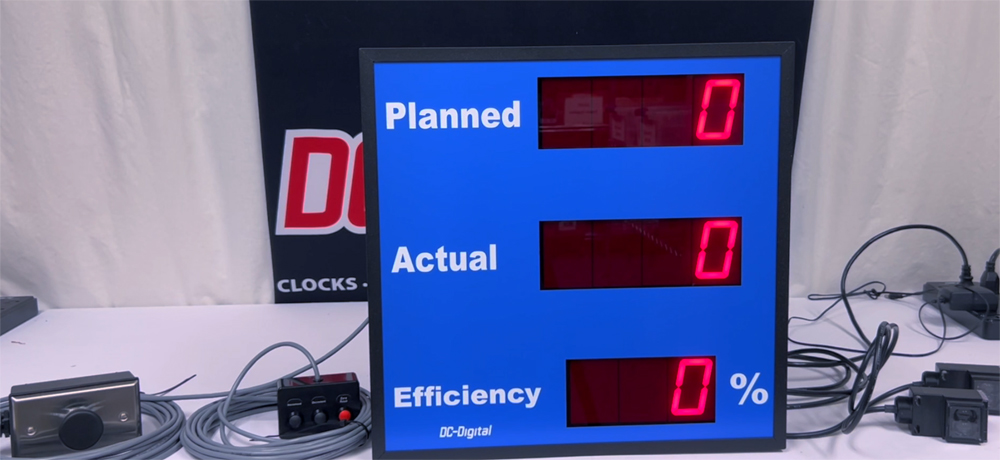

The DC-25C-2-EFF-RP Digital Production Counter is a custom-built solution designed to support high-accuracy production monitoring in pharmaceutical and healthcare environments. This unit is shipping to Formulated Solutions, where it will be used to track production output, distinguish good products from rejected ones, and clearly display real-time efficiency on the factory floor.

At its core, this model is designed to count objects moving through a production line and determine how efficiently a machine is producing acceptable product. This is accomplished using two diffusive reflective area sensors mounted on the right side of the enclosure. One sensor tracks the total number of products that pass through the process, referred to as the Planned count. The second sensor tracks only the products that successfully meet quality standards, referred to as the Actual count. Using these two values, the unit automatically calculates and displays the production Efficiency percentage in real time.

During operation, when an object passes in front of the first diffusive reflective sensor, the Planned count increments. When an object passes in front of the second sensor, the Actual count increments. As the Actual value increases relative to the Planned value, the Efficiency display updates accordingly. This gives operators immediate visibility into how effectively the production equipment is producing good product and helps identify inefficiencies as they occur.

In addition to automated sensor inputs, the DC-25C-2-EFF-RP also supports manual data entry through two remote controls located on the left side of the enclosure. These controls allow operators to adjust counts as needed, providing flexibility in environments where visual inspection or manual verification is required.

The wired palm switch is dedicated to the Planned section. It includes three functions: Increment, Decrement, and Reset to Zero. Each press of the Increment button adds one digit to the Planned count, while Decrement subtracts one digit. Pressing and holding the Reset button for three seconds clears the Planned value back to zero. This allows one operator to manually track total throughput if needed.

The stainless steel environmentally sealed push-button remote is dedicated to the Actual section. Each press adds one digit to the Actual count, representing a verified good product. This ensures accurate tracking of acceptable output, even in demanding industrial or clean production environments.

From a hardware standpoint, the DC-25C-2-EFF-RP is built for durability, visibility, and reliability. The enclosure is constructed from aluminum and finished with a fingerprint-resistant black powder coat. It measures 16 inches wide, 15.75 inches tall, and 2.25 inches deep, making it suitable for wall mounting in production areas without occupying excessive space.

The unit features large, high-visibility LED digits measuring 2.3 inches tall, readable from distances up to 120 feet. Both the Planned and Actual sections provide four-digit displays, while the Efficiency section displays up to three digits to clearly represent percentage values.

Key hardware and system features include:

- Aluminum, fingerprint-resistant, black powder-coated enclosure

- Two diffusive reflective infrared object proximity sensors with mounting hardware

- Detection range up to 10 feet

- Four-digit Planned and Actual displays

- Three-digit Efficiency percentage display

- 2.3-inch LED digits visible up to 120 feet

Power is supplied via a universal 120 to 240 VAC input, and the unit comes equipped with a six-foot, three-prong power cord. For installation flexibility, the enclosure includes two adjustable teardrop knockout mounting tabs located on the upper rear corners, allowing for secure and precise wall mounting.

Accessories included with this custom order further enhance usability in production environments. The wired 4mm palm switch supports full control of the Planned count, while the environmentally sealed push-button provides reliable input for the Actual count. Together with the diffusive reflective sensors, these inputs allow the DC-25C-2-EFF-RP to deliver accurate production data with minimal operator intervention.

The DC-25C-2-EFF-RP Digital Production Counter delivers clear, real-time insight into production efficiency, making it an ideal solution for pharmaceutical and healthcare manufacturers like Formulated Solutions that require accuracy, reliability, and immediate performance feedback on the production floor.

Watch tutorial video on YouTube

See Other Efficiency Counters

See DC-Digital Store

See Similar Product

No Comments