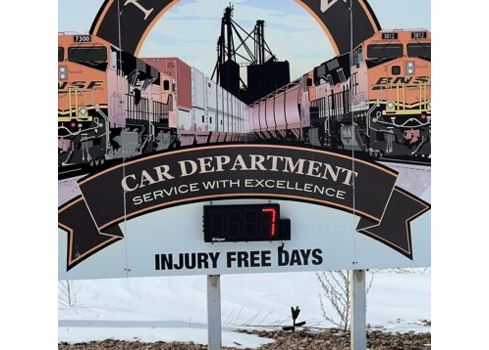

Railroad Safety Scoreboard Days Incident Injury Free

BNSF Railroad Prioritizes Safety with DC-Digital’s Outdoor Days Injury-Free Counter Scoreboard

BNSF Railway, one of North America’s largest freight railroads, has always been committed to safety as a top priority. With thousands of employees working in dynamic and sometimes hazardous environments, maintaining a strong safety culture is crucial. To reinforce this commitment and keep safety awareness front and center, BNSF has partnered with DC-Digital to manufacture and install a Days Injury-Free Counter Scoreboard for outdoor use. This bold and highly visible digital display serves as a continuous reminder of the railroad’s safety milestones, encouraging vigilance and responsibility across all work sites.

Why a Digital Days Safe Counter?

In industries like rail transportation, where heavy machinery, high speeds, and complex operations create potential risks, tracking and celebrating injury-free days can boost morale and reinforce a safety-first mindset. The DC-Digital Safety Scoreboard prominently displays the number of consecutive injury-free days, ensuring that employees and visitors alike remain aware of their safety record.

This LED digital scoreboard provides real-time updates, allowing BNSF to instantly reflect progress and reset the count if necessary. The high-brightness display ensures maximum visibility, even in outdoor conditions, making it an effective tool for raising safety awareness at all times.

Features of the DC-Digital Days Safe Counter Scoreboard

BNSF Railway selected DC-Digital’s outdoor-rated safety scoreboard for its durability, clarity, and ease of operation. Some of its key features include:

- High-Visibility LED Display – The large, bright digits can be seen from a significant distance, ensuring all employees and site visitors can easily read the safety count.

- Rugged, Weather-Resistant Design – Built for outdoor use, the scoreboard withstands harsh weather conditions, from heavy rain to extreme temperatures.

- Wireless or Hardwired Control Options – Authorized personnel can quickly update or reset the injury-free count using a remote or centralized control system.

- Automated Time Tracking – The scoreboard is designed to increment daily, keeping an accurate record of safe workdays without manual intervention.

- Custom Branding – BNSF’s version of the scoreboard prominently features its logo and corporate safety message, reinforcing company-wide commitment to injury prevention.

Boosting Safety Culture Through Visibility

The presence of a Days Injury-Free Counter Scoreboard serves multiple purposes:

- Reinforces Safety Awareness – When employees see the safety count increasing daily, they are reminded of their role in maintaining a secure work environment.

- Encourages Accountability – Workers take greater ownership of their actions, knowing that the displayed number reflects their collective efforts.

- Motivates Teams to Achieve New Milestones – Seeing a high count fosters a sense of pride and motivates workers to push for new safety records.

- Acts as a Quick Reference for Leadership – Managers can easily monitor the site’s safety performance without needing to check reports.

A Long-Term Investment in Safety

BNSF Railway’s decision to implement DC-Digital’s injury-free counter demonstrates a proactive approach to safety. By making injury prevention a visible and tangible achievement, the railroad is fostering a culture where every team member actively contributes to maintaining a safe work environment.

For other companies in rail transportation, manufacturing, construction, or any high-risk industry, investing in a digital safety scoreboard can significantly improve awareness, morale, and overall workplace safety performance.

Interested in implementing a Days Safe Counter for your organization? Visit DC-Digital to explore custom solutions for your safety initiatives.

See NETWORK controlled Safety scoreboard Video

No Comments