Network Controlled Safety Scoreboard with Dates and Days Since Last Incident-Accident-Injury

- By : DC-Digital sales & marketing

- Category : Counters, Days Counter, Days Without and Accident Timer, Network, Network Displays - Browser Based, Number Displays, Safety Awareness Scoreboards

- Tags: Network Browser Based Displays no software required, network controlled computer controlled safety scoreboard days without incident accident first aid, Network Controlled Displays

Introduction

Workplace safety is a top priority for every organization, and awareness is key to preventing accidents. A network-connected factory safety scoreboard provides real-time visibility into workplace safety metrics, helping employees stay informed and vigilant. This innovative digital display keeps track of days without incidents and dates of last medical treatments or first-aid cases, ensuring safety remains at the forefront of operations.

Key Features of the Safety Scoreboard

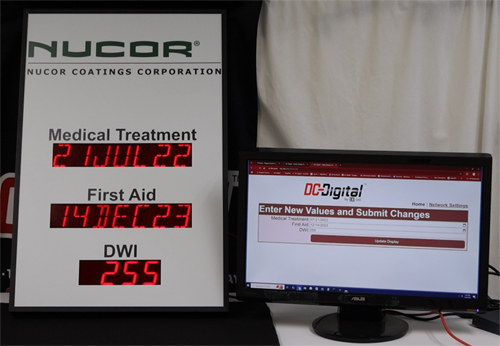

1. Network-Connected for Remote Access

Unlike traditional scoreboards that require manual updates, this Wi-Fi or Ethernet-connected display allows management to update and monitor safety statistics remotely via:

✅ Computer

✅ Tablet

✅ Smartphone

Supervisors can log in and update two static dates:

- Date of the last medical treatment

- Date of the last first-aid case

Additionally, the system automatically increments the “Days Without Incident” counter every 24 hours, eliminating the need for manual changes.

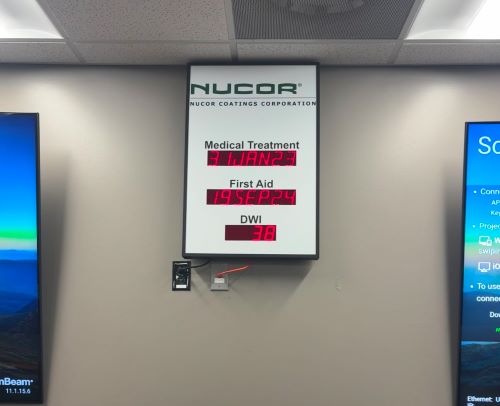

2. Large, High-Visibility Display

The scoreboard features 2.3-inch LED digits that can be read from up to 120 feet away. This ensures that employees across the facility can easily see the safety statistics at all times, reinforcing safety awareness.

3. Durable & Customizable Design

- All-aluminum extruded enclosure: Provides durability in industrial environments.

- Acrylic vinyl front: Designed with customer-specific artwork to align with company branding and messaging.

4. Promotes a Safety-Conscious Culture

Displaying real-time safety stats creates awareness among employees, reminding them daily of the importance of accident prevention. Studies show that visible safety metrics help reduce workplace incidents by encouraging employees to adopt safer work habits.

How It Works

- Network Connectivity: Connect the scoreboard to the factory’s Wi-Fi or Ethernet network.

- Remote Access: Authorized personnel can access the system remotely to update or review data.

- Automatic Day Counter: The system updates the “Days Without Incident” count every 24 hours.

- Customizable Display: Personalize the scoreboard with company branding and safety messages.

Why Your Facility Needs This Safety Scoreboard

✅ Prevents complacency by keeping safety top-of-mind.

✅ Increases awareness and accountability.

✅ Remote updates make it easy to manage safety data.

✅ High-visibility LED display ensures easy readability.

Final Thoughts

A network-connected factory safety scoreboard is a simple yet powerful tool to enhance workplace safety awareness. By providing real-time, remote-accessible safety data, this system helps reinforce a culture of safety, reduce workplace incidents, and improve overall employee well-being.

See full video demonstration: DC-2518ALN-DAYS-DATES

DC-Digital contact us page: Contact us

No Comments