Network, POE Webpage Down-Timer w/ ANDON Light for Automobile Factories

- By : DC-Digital sales & marketing

- Category : Clocks, Count Up timer, Countdown Timer, Manufacturing, Multi-purpose, Network, Network Displays - Browser Based, Number Displays, System Synchronized Clocks, Time of Day

- Tags: 12 24 hour, Andon Light, Count Down Timer, count-up-timers, DC-40, Dc-Digital, network, Network Browser Based Displays no software required, network clock, Network Clocks, Network Controlled Displays, Network count up timer, network-clock, Network-Clocks Webpage-Clock Browser-Clocks NTP-Clocks outdoor-Clocks, POE Powered

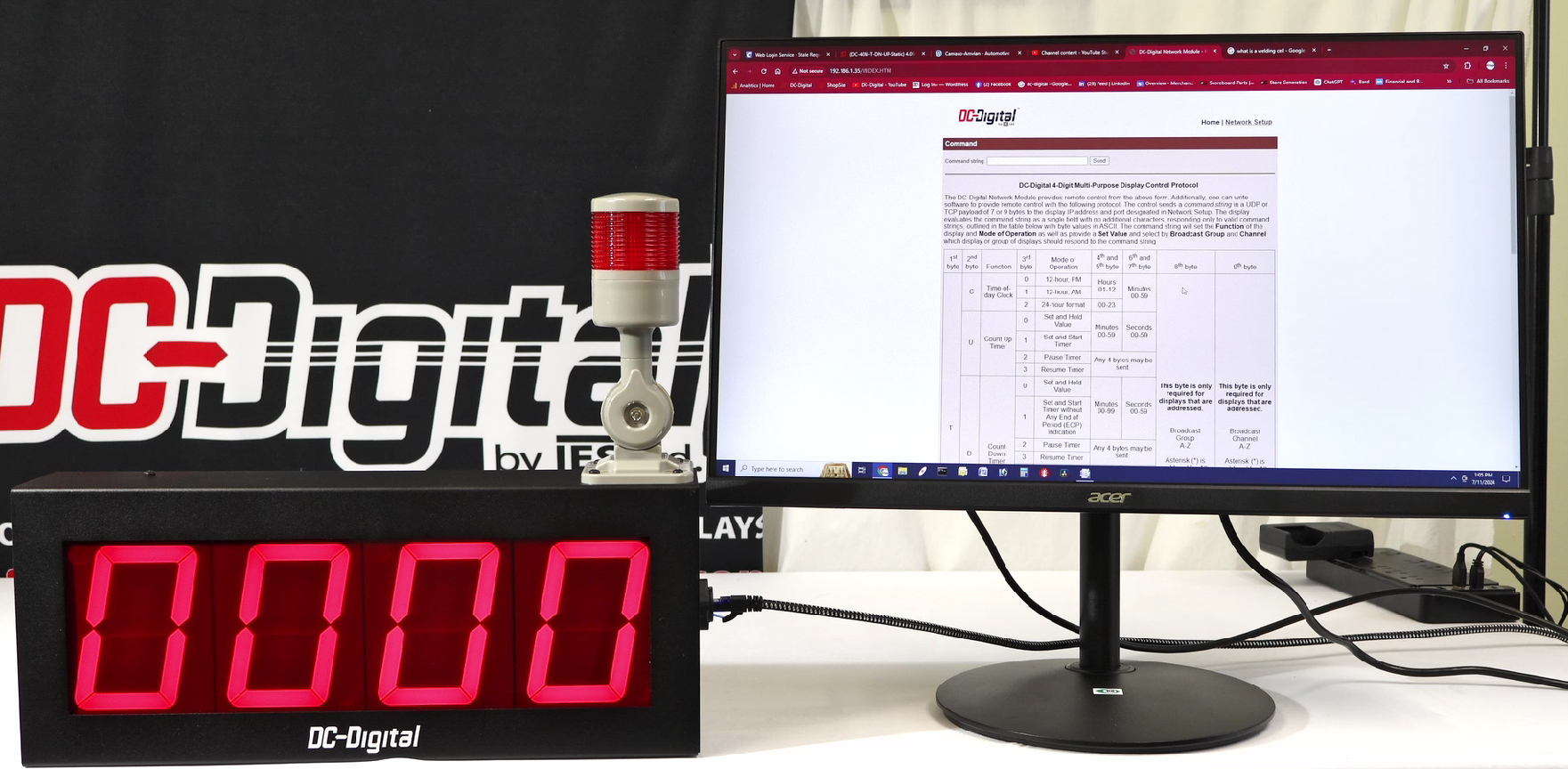

This custom DC-40N-T-DN-UP-Static-POE Network Webpage Welding Cell Countdown Timer was designed specifically for Camaco Columbus MFG., an automobile seating manufacturer, to support precise welding cell operations. The primary goal of this system is to provide a clear, reliable countdown that indicates when a welding machine cycle has completed, triggering a visual and audible alert for operators on the production floor.

The unit operates as a fully networked, plug-and-play solution using a single RJ-45 Ethernet connection. Power and data are delivered via POE, eliminating the need for additional wiring while allowing seamless integration into the facility’s existing network infrastructure. Once connected, users interact with the unit entirely through a browser-based webpage, where command strings are entered to control display modes, timing functions, and alerts.

From the network webpage, commands are entered into the command string field at the top of the interface, with available command codes clearly listed within the page. All commands must be entered in capital letters. Once a command is submitted, the display responds instantly, allowing operators and engineers to tailor the timer’s behavior to the specific needs of the welding cell.

The unit supports displaying the current time of day in both 12-hour and 24-hour formats. By entering the appropriate time clock command, users can quickly synchronize the display to match facility standards or operational preferences. This makes the device useful not only as a timer but also as a visible reference clock on the production floor.

In addition to time-of-day functionality, the unit can operate as both an up-timer and a down-timer. The up-timer mode allows users to set and hold a starting value, resume timing, or pause the timer as needed. A visual indicator on the display confirms when the unit is operating in up-timer mode, making it easy to distinguish from other functions at a glance.

For Camaco’s welding application, the countdown timer functionality is the key feature. The down-timer operates in a similar manner to the up-timer but includes additional end-of-period options that are critical for automated workflow signaling. When the countdown reaches zero, the unit can activate an end-of-period alert that clearly indicates the welding process is complete.

Key countdown and alert capabilities include:

- Countdown timing with precise start, pause, and resume control

- End-of-period ANDON light activation when the timer reaches zero

- Audible piezo alarm to notify operators immediately

- Optional flashing display at end of period for high-visibility alerts

When the countdown reaches zero, the ANDON light mounted on the top right side of the enclosure illuminates red, and the piezo alarm sounds to signal completion. The light remains active until a new command is entered, ensuring the alert is not missed in busy production environments. An alternate end-of-period mode allows the main LED display itself to flash instead of triggering the ANDON light, offering additional flexibility based on visibility requirements.

The unit also supports static display modes, allowing it to show fixed numbers, static time values, or numeric displays with colons or decimal points. This is useful for status indicators, reference values, or non-timing-related visual communication within the cell.

Static display options include:

- Fixed numeric display up to 9999

- Static time display in 12-hour or 24-hour format

- Decimal or colon display for customized visual formatting

From a hardware standpoint, this model is built for industrial environments. The enclosure is constructed from tough 14-gauge aluminum with a fingerprint-resistant black powder-coated finish. Measuring 16 inches wide, 6 inches tall, and 3 inches deep, it is designed to withstand demanding shop-floor conditions while maintaining a clean, professional appearance.

The four-inch LED display is highly visible from distances of up to 200 feet, making it ideal for open production areas. With four digits, the unit can display time of day, count up or down up to 99 hours and 59 minutes using shift digit technology, and even operate with hundredths-of-a-second precision.

Power and communication are handled entirely through the RJ-45 Ethernet connection using POE, which splits data and voltage internally to supply the correct operating power. The enclosure includes rear-mounted knockout options for flexible installation, including 4×4 or 2×4 teardrop configurations.

Available accessories for this custom build include a multi-colored LED ANDON light, a piezo buzzer rated at approximately 24 VDC, and an ultra-high-output panel-mounted buzzer adjustable between 75 and 95 dB. All configuration and control are handled through the built-in network webpage, which is accessible from any standard web browser such as Chrome, Bing, or Yahoo. No operating system dependency or specialized software is required.

This custom DC-40N-T-DN-UP-Static-POE solution provides Camaco Columbus MFG. with a reliable, network-driven method for tracking welding cycle completion, improving visibility, efficiency, and operator awareness across the production floor.

See Similar Product: DC-40N-T-DN-UP-Static

See tutorial video on YouTube

See DC-Digital Store

No Comments