Repurposing Vehicle Service Bay timer & Data Log for Factory Production of Garage Doors

At DC-Digital, we take pride in providing custom timing and counting solutions that fit the unique needs of our clients. One of our latest projects is the DC-40T-UP-TERM-BAY-TIMER, a fully customized production processing timer designed specifically for Haas Garage Doors. This innovative unit was engineered to help them monitor and log the number of cars being serviced in their workspace — all through a seamless network-based system.

Smart Network Functionality for Real-Time Logging

What truly sets the DC-40T-UP-TERM-BAY-TIMER apart is its network functionality. This timer doesn’t just track time — it logs each vehicle’s activity automatically using an internet connection and our custom-built web interface.

Here’s how it works:

- The unit connects to the internet via a standard Ethernet cable.

- Once connected, it links directly to DC-Digital’s custom web page — no third-party software or installation required.

- By simply entering the MAC address into your browser’s URL bar, users gain instant access to a live webpage that tracks all vehicle activity in real time.

Each time a car enters or exits the workspace, the system automatically logs that event to the webpage. The diffusive reflective sensor detects when a vehicle is present, and after one minute, once the vehicle leaves, the timer records the event — keeping a running tally of all automobiles processed.

This ensures that Haas Garage Doors can maintain accurate, automated records of workflow activity without any manual data entry, improving both efficiency and accountability in their production process.

Demonstration of Operation

To demonstrate the unit’s function, a simple test can be performed using a piece of paper to trigger the deflective area sensor. By holding the paper in front of the sensor for one minute, the timer begins its count, and the digits visibly increase.

The display can count up to 99 hours and 59 minutes, and every completed cycle is reflected not only on the enclosure display but also on the live web page simultaneously. Once the process resets, the system is ready to log the next car automatically, ensuring continuous and reliable operation.

Hardware and Design

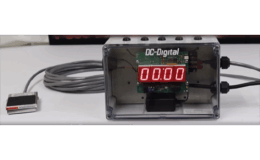

Beyond its smart network capabilities, the DC-40T-UP-TERM-BAY-TIMER is built for durability and professional use in demanding environments.

Key hardware specifications include:

- Enclosure: 14-gauge aluminum, black powder-coated and fingerprint resistant.

- Dimensions: 16″ wide × 6″ tall × 3″ deep.

- Display: 4-inch high-intensity LED digits, visible up to 200 feet away.

- Digit Count: 4 digits capable of timing up to 99:59 hours.

- Power Source: 120–240 VAC wall adapter with a 6 ft cord (Ethernet-powered for this custom model).

- Mounting Options: Compatible with 4×4 or 2×4 electrical rough-in box tear-slotted knockouts. Optional handles and tripod mounts available upon request.

- Sensor Input: Diffusive reflective sensor, hardwired into the enclosure terminal, detects objects up to 10 feet away.

Designed for Precision and Efficiency

The DC-40T-UP-TERM-BAY-TIMER is a perfect example of how DC-Digital’s products can be custom-tailored for industrial applications. By combining traditional timer functionality with modern networking and data logging, this model allows facilities like Haas Garage Doors to maintain real-time oversight of operations with minimal user intervention.

This isn’t just a timer — it’s a comprehensive production management tool, built to streamline workflows and enhance productivity through precise, automated tracking.

See similar product: DC-40T-UP-TERM-BAY

See our video: DC-40T-Up-Term-Bay

See DC-Digital Store

See Other Vehicle Service Timers

No Comments