Job Logging, Project Counter with Large Display, Network Interface for Manufacturing Companies

- By : DC-Digital sales & marketing

- Category : Counters, Manufacturing, Network, Production Counter

- Tags: clock, Conveyor Parts counter, count and report count through network, Counter Parts, Manufacturing-Counter, Network Parts counter, Powder coating parts counter, Process-Counter, Process-Counters, Prodcution-Counter, Production Counter

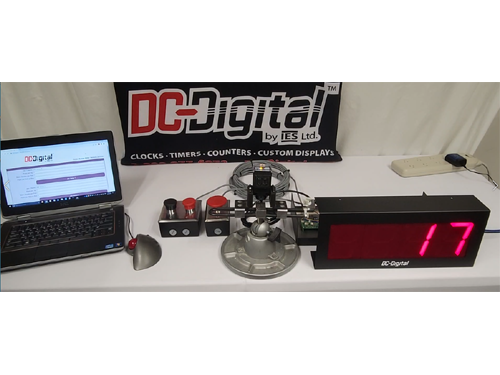

F3 Metalworx has been working with DC-Digital to create a custom product that would help in counting the number of parts being made. Designed specifically for high-efficiency production environments, this system delivers accurate and automated part counting for each jig, box, or container moving down your conveyor belt — all while keeping operators informed via both a digital display and a network-based webpage. At the core of the system is our DC-40N-C Counter Unit, a rugged, precision-built LED counter housed in a black powder-coated aluminum enclosure. The casing features 4×4 or 2×4 teardrop knockout drops, allowing for flexible mounting in various industrial environments.

The count system uses a diffused reflective area sensor that accurately detects objects from up to 10 feet away, enabling hands-free tracking of parts on the production line. As each part or container passes through, the sensor signals the counter to register the event — tracking the number of items per jig with precision.

In addition to automation, the system also includes two environmentally sealed push button switches with 25 feet of cabling for enhanced operator control. The first button allows for manual incrementing and decrementing of the total count by 1 — ideal for quick corrections or manual inputs. The second button is used to increment the set number of jigs to be counted per pass, integrating directly with the network system.

The real-time data is not only shown on the counter display but is also mirrored on a dedicated network webpage. Through this interface, clients can:

– Set the number of jigs to count per pass

– Monitor totals remotely

– Adjust values on the fly

– And maintain historical data for each jig or process

What sets this system apart is its integrated network webpage, which not only displays the real-time count but also logs all counting data for each jig or process. This logging feature ensures historical tracking, auditability, and the ability to analyze production trends over time — no additional software required.

Whether you’re counting batches, managing multiple jigs, or tracking process flow in a high-volume facility, this system gives you a reliable, networked solution to streamline your production data.

See similar product: DC-40C-PKG-SHRT

DC-Digital Sensor

See tutorial video on YouTube

No Comments