Network Controlled Safety Scoreboard with Dates and Days Since Last Incident-Accident-Injury

- By : DC-Digital sales & marketing

- Category : Counters, Data Controlled Displays, Days Counter, Days Without and Accident Timer, Network, Network Displays - Browser Based, Number Displays, Safety Awareness Scoreboards

- Tags: Custom Built to Order, Days since last accident, days without an accident, DC-256, Dc-Digital, Indoor-outdoor, Network Browser Based Displays no software required, network controlled computer controlled safety scoreboard days without incident accident first aid, Network Controlled Displays, Nonvolatile Memory

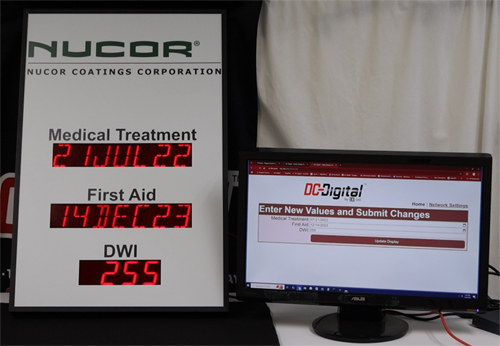

Introducing our DC-2518ALN-Days Without An Accident Display, a fully networked safety scoreboard designed to keep your team informed, aware, and accountable. This display allows you to track and manage three critical safety metrics: the date of last medical treatment, the date of last first aid incident, and the continuously running count of days without an incident. Built for reliability and ease of use, it gives safety managers and supervisors the flexibility to update information from a remote location over your network—no ladders, no manual resets, and no downtime.

What makes the DC-2518ALN unique is its network capability. While many safety displays require physical interaction to reset or update, this model connects directly to your network, allowing you to access and control it through a standard web browser. Whether you’re using Google Chrome, Mozilla Firefox, Microsoft Edge, or even accessing it from your phone, the interface provides a straightforward way to update dates and confirm changes in real time.

The display operates with two types of tracking:

The Date of Last Medical Treatment and Date of Last First Aid are statically entered values. Once you input those dates, they remain displayed until the next event occurs and you manually update them.

The Days Without Incident counter works differently. When you update the display following an incident, the counter resets and then automatically increments once every 24 hours. This creates a true running day count from the last recorded incident. The increment timing begins either when you update the display or when the unit is powered up, ensuring accurate tracking moving forward.

Accessing the display on your network is simple. We provide a small IP Setup utility available on our website. By searching “IP Setup” on our site, you can download the zip file containing a lightweight executable program. Once installed, the program scans your network and identifies compatible network cards under the Net Burner brand. You simply select the DC-2518ALN-DAYS model from the list, launch the web interface, and log in using the default lowercase credentials “username” and “password.” From there, you can configure DHCP settings or assign a static IP address, along with mask, gateway, and server information as needed for your network environment.

Inside the web interface, you can:

- Change the date of last medical treatment

- Change the date of last first aid

- Reset and update the days without incident counter

- Use the built-in calendar for quick date selection

- Update the display instantly from your remote computer

- Refresh the browser to confirm updated values

The DC-2518ALN stores all dates and counters in nonvolatile memory. In the event of a power failure, the display retains its data. When power is restored, it automatically resumes operation with the previously stored dates and continues counting days without incident correctly. This ensures your safety metrics remain intact and accurate, even through outages.

From a construction standpoint, the enclosure is built from durable aluminum, providing strength while maintaining a clean, professional appearance. The front is LEXAN, offering added protection and clarity. All artwork and labeling are produced in-house at our art facility. We print and apply indoor-outdoor vinyl graphics directly to the face of the display, allowing for custom branding, company names, and tailored messaging that aligns with your safety program.

Installation is straightforward and flexible. On the back of the unit, an access plate allows you to connect both the network cable and power cable cleanly. Adjustable keyhole mounting tabs are included, enabling you to hang the display securely on wall screws. The tab spacing can be adjusted to accommodate different mounting requirements, making it easy to install in a break room, near a time clock, on the production floor, or in any high-visibility area where safety awareness matters most.

Key features of the DC-2518ALN-Days Without An Accident Display:

- Fully network-enabled remote updating

- Static date tracking for medical treatment and first aid

- Automatic 24-hour incrementing days-without-incident counter

- Web-based interface accessible from any browser or smartphone

- Nonvolatile memory for power-loss protection

- All-aluminum enclosure with LEXAN front

- Custom indoor-outdoor vinyl artwork produced in-house

- Adjustable keyhole mounting tabs for easy installation

The DC-2518ALN is more than just a display—it’s a tool for reinforcing your safety culture. By providing accurate, visible, and easily managed safety metrics, it helps promote accountability and keeps workplace awareness front and center every single day.

See product: DC-2518ALN-DAYS-DATES

See full video demonstration on YouTube

DC-Digital contact us page: Contact us

No Comments