How Opto Boards Supports Input Devices for our Timing and Counting Products

- By : DC-Digital sales & marketing

- Category : Clocks, Competition Timers, Count Up timer, Countdown Timer, Counters, Days Counter, Elapsed Timer, Electronic component, Manufacturing, Production Counter, Provides protection, Timers

- Tags: isolation board, remote control circut board, sensor input, sensor interface, terminal block

A baker smiles as the timer hits zero, sliding a tray of steaming, golden-brown rolls from the oven. At the zoo, children with puffed cheeks and wide eyes watch the seconds tick upward, testing how long they can hold their breath to match a hippo’s underwater stamina. In a factory, a worker stops a timer, noting how long their latest project took to complete.

These moments seem simple — a timer beeps, a display counts up, a project is measured. But have you ever wondered about the hidden technology that makes them possible? Behind each perfectly timed event is a network of components working silently in the background.

One of the most important? A small but powerful circuit board called an opto board.

What an Opto Board Does

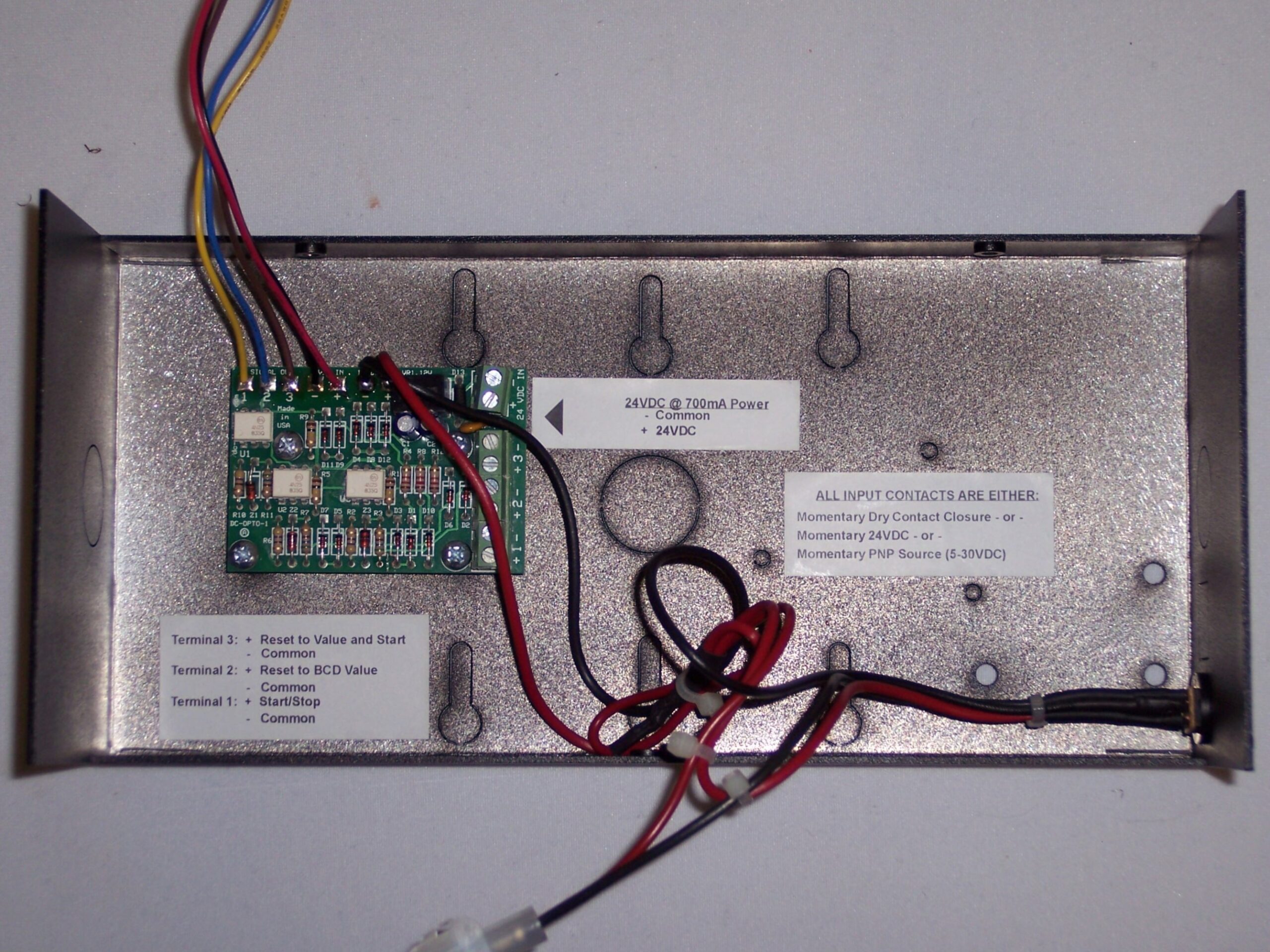

At DC-Digital, our standard opto boards are the unsung heroes of many of our timing devices. Acting as both a connector and a protector, these boards allow input from multiple devices—such as switches, sensors, and PLCs (programmable logic controllers)—while safeguarding sensitive electronics from electrical interference.

Think of them as gatekeepers: signals come in from the outside world, but the board’s opto-isolators filter and protect those signals before they reach the main timer circuitry. This ensures reliable performance, even in electrically noisy environments like factories, sports arenas, or laboratories.

Multi-Input from a Single Enclosure

Our DC-Opto 1 Board supports up to three separate input controls—each with its own dedicated terminal on the PCB. Each input has its own opto-isolator, preventing cross-talk or interference between devices. Each input can handle contact closure or PNP signals up to 24 volts, isolating and translating the signal into what the connected display needs for proper operation.

For customers who need it, the board can also double as a power source for connected input devices, simplifying system design and installation.

Engineered for Reliability

Every opto board we produce has been designed and tested in-house by our engineers, evolving over the years to meet the demands of diverse applications. Using through-hole manufacturing, the DC-Opto 1 Board is built for durability and measures roughly the size of a credit card. Despite its compact footprint, the board contains a dense network of diodes, resistors, and other components working together to ensure flawless signal handling and protection.

From industrial automation to sports timing to educational environments, our opto boards are a staple technology that helps keep the world’s clocks, counters, and timers running smoothly—quietly doing the behind-the-scenes work so the visible moments can shine.

Why It Matters

Without this type of input device, multi-control timing systems wouldn’t be as reliable, safe, or versatile. The next time you see a perfectly timed event, you might think about the hidden hardware inside—like the DC-Opto 1 Board—that quietly makes it all possible.

See products that contain these protection boards: DC-Digital Countdown Timers-Terms

See all products: DC-Digital

Contact us at DC-Digital for more info: Contact us!

No Comments