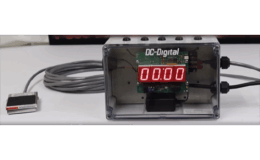

Oil Change Service Timer

Vehicle oil changes have never been faster and today and in the future it will almost be a competition. Your service center will be the fastest in town!

- 4 Inch Digits – Can be viewed up to 200 ft. away

- 10 ft. adjustable no contact sensor with mounting hardware and 25ft. cord

- Durable all aluminum enclosure

- 1 activation resets it to zero and starts count up max. 99 hrs.

No Comments