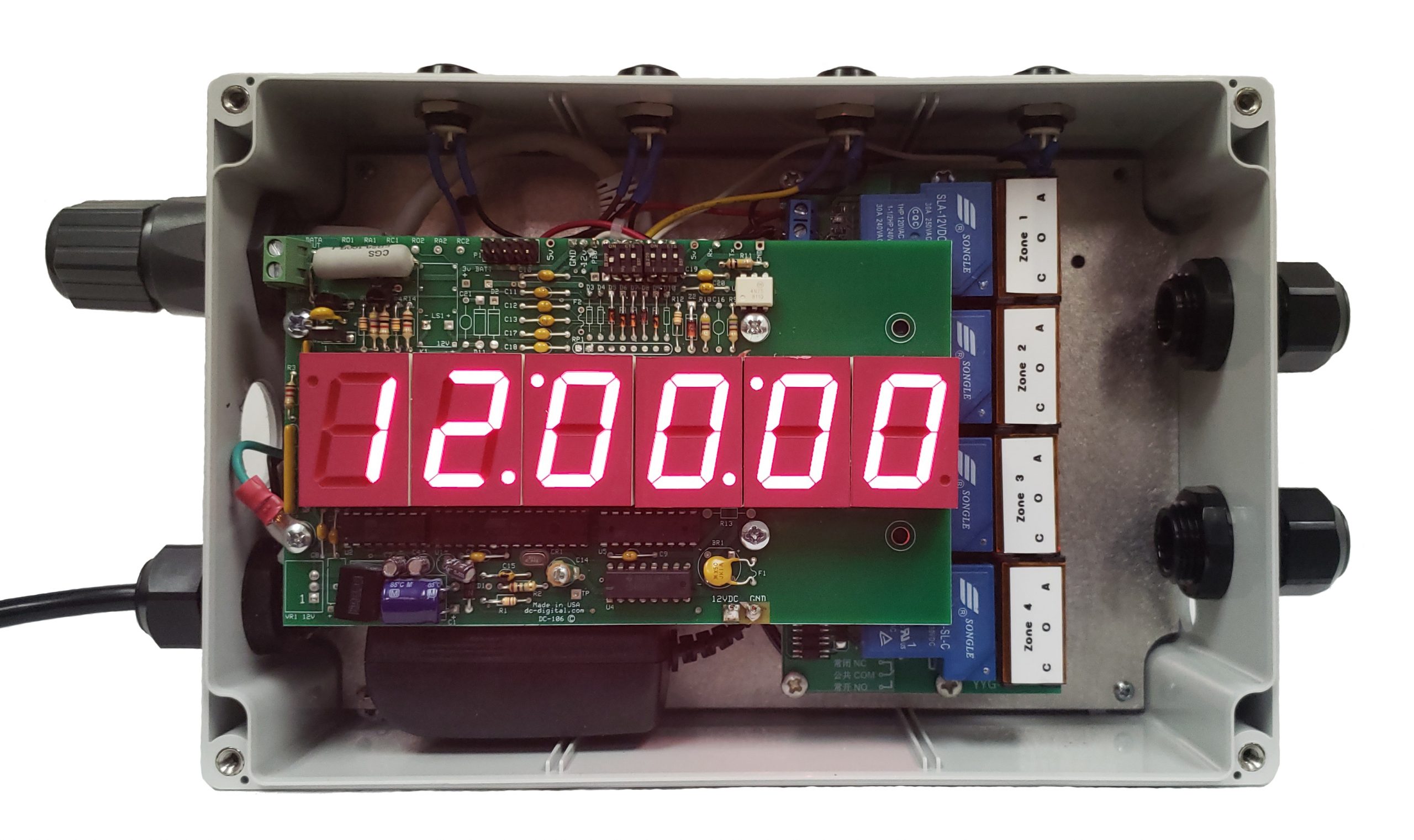

Computer Controlled 4-Relay Module for Shift or Class Change.

- By : DC-Digital sales & marketing

- Category : Clocks, Network, Timers

- Tags: Network Controlled Displays

Now you can setup an infinite number schedules for all of your bells, lights, doors, shifts all in one package. Computer controlled using our EZ-Time Windows 10 based software and the DC-RM-10-4 virtual port software, from anywhere.

Control your class changes or Shift changes using our EZ-Time windows based scheduling software or its on board Webpage. Connect it via network LAN, WAN or Peer to Peer (Direct). Ring shift or class bells, turn on or off lights, close or open doors (360 Watts per SPDT Relay). EZ-Time or can be set using a webpage (send code). The relays inside can be set using the bell schedule found in EZ-Time or can be triggered instantly using the push button switches on top of the case or the built in Webpage.

Each relay zone can be triggered to go off independently, allowing for up to 4 different bell schedules to be controlled by one device. Each relay is rated at 360W and has been tested using both AC and DC power. Devices can be connected to the relays using either the Open or Closed terminals, allowing for a wide range of flexibility when connecting devices.

How It Works

We made a couple of videos showing how to use the DC-RM-10N-4. This first video shows how to find the device on a network and use the webpage to set the time and control the relays.

We made an additional video in order to showcase the use of EZ-Time over a network connection using the DC-RM-10N-4. This next video explains how to set up a Virtual Com Port in order to use EZ-Time over a network connection. This video should be watched after you have already found the DC-RM-10N-4 on your network and have opened the webpage.

No Comments